crusher selection guide

Crusher Wear Parts Selection Guide (External) 001

Crusher Wear Parts Selection Guide (External) 001 Crusher Wear Parts Selection Guide JAWS, CONES & IMPACTS Aug. , issue 001 CRUSHER WEAR PARTS BRIEFING CONE CRUSHER WEAR PARTS Wear Parts Materials in Properties Manganese Wear Mechanisms in Crushing Chamber Wear Factors Feed Material Properties

Learn MoreCrushing Equipment Selection - Mineral Processing & Metallurgy

2/28 · In any quarrying or open-pit mining operation the primary crusher, shovel, and transportation equipment should function as a team; therefore these three items of equipment, when possible, should be considered as complements of each other when making selections. This is especially important with respect to the crusher and the shovel.

Learn Moreselection crusher

MANUAL CRUSHER SELECTION 1 Determine the maximum feed size 2 The minimum feed size to the crusher must always be less than 25mm 1 in either open or closed circuit 3 Determine the total tonnage throughput of the crusher a Open Circuit

Learn MorePDF Handbook of Crushing - TerraSource GlobalPDF

process of selecting and sizing a crusher to a series of formulas. The selection process is largely based on experience and testing — experience with actual field applications and laboratory tests that show how a given material will be reduced by a given crusher type. The main purpose of this handbook is to explain the

Learn MoreCement Crusher Selection Guide-CHAENG

The hammer crusher and impact crusher are the most common type used in the cement industry. Both of them rely on the impact principle and also have the function of a coarse crushing, secondary crushing, and fine crushing. The main difference between the

Learn MoreHow To Choose Cement Crusher? | Jaw Crusher, Cone

10/30 · AGICO Cement is a cement equipment manufacturer, we supplies jaw crusher, cone crusher, impact crusher, hammer crusher and other cement manufacturing machines,

Learn MorePDF Crusher Wear Parts Selection Guide Rev 002PDF

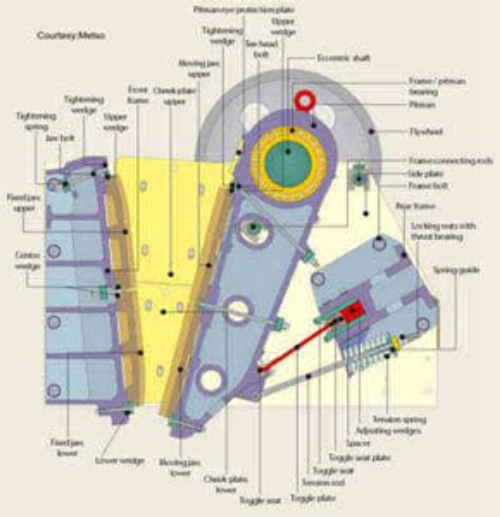

IMPACT CRUSHER WEAR PARTS Jaw Die Selection Features V2 Jaws V2 Cheek Plates V1 Jaws & Cheek Plates CSS & Feed Opening - C2, C3 & C4 Blow Bars Selection Blow Bars Curtain Liners CONTENTS 02-05 06-08 09-10 11-12 02 CRUSHER WEAR PARTS SELECTION GUIDE. Manganese steel is the most common material for crusher wears. The wear resistance of

Learn MoreCrusher Wear Parts Selection Guide

Crusher Wear Parts Selection Guide JAWS, CONES & IMPACTORS CRUSHER WEAR PARTS BRIEFING CONE CRUSHER WEAR PARTS Wear Parts Materials in Properties Manganese Wear Mechanisms in Crushing Chamber Wear Factors Feed Material Properties JAW CRUSHER WEAR PARTS IMPACT CRUSHER WEAR PARTS

Learn MoreCement Crusher Selection Guide-CHAENG

Cement Crusher Selection Guide-CHAENG. 2020-05-29 10:03:58. Share to: PDF Download. The cement crusher is the necessary equipment in the cement production line. with the wide application of cement and higher requirement for the cement manufacturing process, the cement crusher gets more and more hot in the cement industry.

Learn MoreCrusher (Immersive Engineering) - Official Feed The Beast Wiki

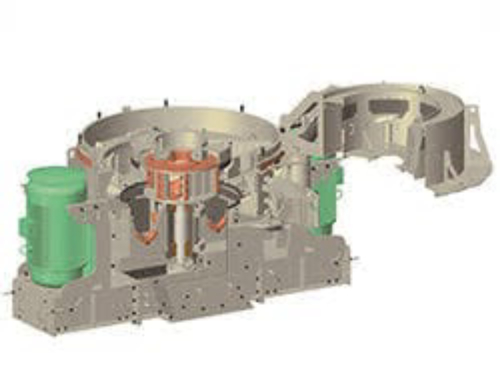

The Crusher is a 3×5×3 multiblock added by Immersive Engineering. It is used for crushing ores into grit, which is more efficient than normal smelting. Contents 1 Construction 1.1 Bill of materials 1.2 Assembly 1.3 Bill of materials 1.4 Assembly 2 Usage Construction Current Bill of materials 10 Steel Scaffoldings 10 Light Engineering Blocks

Learn MoreCrusher | Definition | Crusher Selection And Types of Crusher

So, during selection keep following points in mind and find whether the crusher is able to do these specific functions or not. Type of material to be crushed with the crusher The maximum size of the stones that crusher is able to face Feeding method to the crusher Capacity per hour, capacity per day of the crusher Efficiency of the crusher

Learn MoreCrusher Wear Parts Selection Guide

The selection of wear parts for your crusher depends on several factors, including the type of rock, the throughput rate, and product size. The following information will help you select the right replacement wear parts. For optimal performance, consider contacting a supplier who has an in-depth understanding of wear patterns.

Learn MoreThe selection guide of crusher from China Juxin Mavchinery

1.Jaw crusher: China Juxin jaw crusher has these featuers of high crushing ratio, uniform particle size, simple structure, stable working, easy maintenance and low costs etc. 2.Hammer crusher: China Juxin hammer crusher has: PC series hammer crusher, PCH series ring hammer crusher, PCK series reversible hammer crusher etc.

Learn Moreselection criteria of crusher

Jaw Crusher Selection Criteria svmarc.in. Soft Starter Selection Guide.Warnings Crusher,jaw.•.Crusher,rotary.Cable selection criteria depends on the circuit and the location of

Learn MoreSelecting the Right Crushing Equipment | Agg-Net

Most crushers used for aggregate production fall into one of three main categories/types: Compressive crushers – which squeeze the material until it breaks. Impact crushers – which

Learn MoreCrushers Selection Guide: Types, Features, Applications - GlobalSpec

Cone crushers. Medium hard to very hard. Abrasive. Dry or wet, not sticky. 3/1 to 5/1. Quarried materials, Sand & gravel. Gyratory crushers. Soft to very hard. Abrasive. Dry to slightly wet, not sticky. 4/1 to 7/1. Heavy mining, Quarried materials. Horizontal shaft impactors. Soft to medium hard. Slightly abrasive. Dry or wet, not sticky. 10/1 to 25/1

Learn Moreallis chalmers crusher screen selection guide

英语网站资料. Contribute to /en development by creating an account on GitHub.

Learn MorePDF Crusher Wear Parts Selection Guide (External) 001PDF

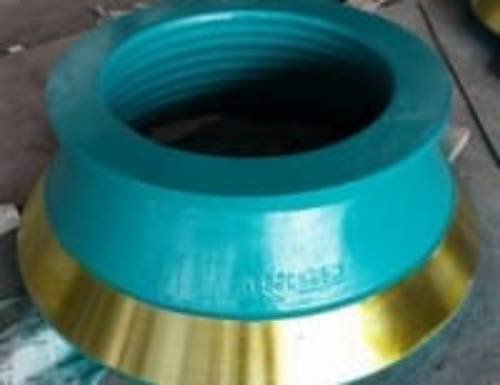

Crusher Wear Parts Selection Guide JAWS, CONES & IMPACTS Aug. , issue 001. CRUSHER WEAR PARTS BRIEFING CONE CRUSHER WEAR PARTS Wear Factors Feed Material Properties JAW CRUSHER WEAR PARTS IMPACT CRUSHER WEAR PARTS Jaw Die Selection Features V2 Jaws V2 Cheek Plates V1 Jaws & Cheek Plates CSS & Feed Opening - C2, C3 & C4 Mantle & Bowl

Learn MoreCrusher Selection And | Xpedia

crusher and screen selection products. as a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size-reduction requirements including, crusher and screen selection, quarry, aggregate, and different kinds of minerals. Cone Crusher Liner Selection Wear Parts For Industry

Learn MorePDF R Crusher Wear Parts Reference GuidePDF

Blow Bar Selection & Application Guide • Blow Bar Part Codes. 5 18% MANGANESE Standard fit on all Jaw & Cone crushers. A good all round liner for all applications. The hardness of a material is a major consideration in the selection of the type of crusher to use. Hardness is a factor in the amount of wear and tear crushers and screens

Learn MoreChoosing the right crusher - Buying Guides DirectIndustry

1/29 · How to choose a crusher? There are several characteristics to consider: The abrasiveness and hardness factor. It is essential to know what material is going to be crushed,

Learn MoreCrushers Selection Guide: Types, Features, Applications

There are several types of industrial crushers available to industrial buyers. These types include: 1. Vertical impactorsuse the weight and friction of the feed (autonomous) or add hammer-like processors. 2. Horizontal shaft impactors spin feed against various surfaces. 3. Jaw crushersfeed materials between See more

Learn MoreHorizontal Shaft Impact Crusher Materials Guide | CMS Cepcor

Manganese Steel Manganese hammers and blow bars are commonly used primary crusher applications and provide high shock resistance and are available in both Mn14% and Mn18% material grades as well as our special MNX50 grade. They are well suited to applications where tramp iron is possible in the feed material.

Learn Moreselection guide for magnetic drum separator crusher

5 conveyor pulley selection guide pulleycore diameter - the outside diameter of the cylindrical body of a conveyor pulley, without coating. finish diameter - the outside diameter of a coated pulley (core diameter 2 times the coatingwrap thickness). face width - the length of a pulleys cylindrical area is intended to act as the contact surface for the conveyor belt.

Learn MorePDF Application guide ® MP Series™ cone crusher wear parts - MetsoPDF

material is fed to the crusher as the fines may cause packing; they can also create high forces in the cavity that may lead to exceedance of the power and/or force limit. • Feed should be well graded with no gaps in the size distribution. 3. Check the power draw The crusher should operate with a steady power draw and as close to full rated

Learn MoreHow To Choose Cement Crusher? | Jaw Crusher, Cone Crusher

10/30 · AGICO Cement is a cement equipment manufacturer, we supplies jaw crusher, cone crusher, impact crusher, hammer crusher and other cement manufacturing machines, any need? Skip to content About Blog Contact CALL US +86 372 5965 148 Home

Learn MoreCrusher Quick-Start Guide — OLCF User Documentation

Crusher also has access to the center-wide NFS-based filesystem (which provides user and project home areas). While Crusher does not have direct access to the center’s High Performance Storage System (HPSS) - for user and project archival storage - users can log in to the Data Transfer Nodes (DTNs) to move data to/from HPSS.

Learn MoreSelection Of Crushers For Lump Ore

Crushers selection guide types features applications ,industrial crushers reduce large rocks, ore, or waste materials to smaller sizes. they are the first level of size reducer; further granularization occurs in grinding mills or pulverizers. crushing devices hold feed material between two solid surfaces and apply sufficient force to fracture or deform that material.

Learn MoreMaterial Selection for Crusher Jaw in a Jaw Crusher Equipment

11/9 · Nov 9, , Abiodun Abioye published Material Selection for Crusher Jaw in a Jaw Crusher Equipment A GUIDE TO SIZE-REDUCTION SYSTEM DESIGN - 1. Article Sep 1976 F.Milton Lewis James L

Learn MoreIndustrial Crushers Selection Guide | Environmental XPRT

The plant's capacity and the size of the feed material are the main factors in selection of a primary crusher. To ensure good performance of the primary plant and prevent production losses, it is necessary to have an adequate correlation between the size of the feed material and the dimensions of the crusher feed opening.

Learn MorePDF Guide to the Proper Selection and Sizing of Industrial Crushers - ThomasnetPDF

Guide to the Proper Selection and Sizing of Industrial Crushers. Crushers are machines that use impact, shear, compression or abrasion to reduce a variety of solid products to a desired particle size range. Delumper® brand crusher are crushers specifically built by Franklin Miller Inc. that are versatile, high end industrial crushers designed for processing such materials as chemicals, minerals, food, food ingredients, pharmaceuticals, grain, fertilizer, coal, soap and more.

Learn More