jaw crusher material

Aggregate Crushers - High-efficiency And Eco-friendly

Next, let me introduce to you the aggregate crusher types. Jaw Aggregate Crushers - Large Feeding Port For Crushing Large Materials. Aggregate jaw crusher is mainly used for processing bulk material. Its maximum feed size can reach 1200mm*1600mm, which can meet the needs of processing large pieces of construction waste aggregate.

Learn MoreJaw Plate Materials | Crusher Mills, Cone Crusher, Jaw Crushers

Jaw Plates-Jaw Plates Manufacturers, Suppliers and Exporters . jaw plate price. Min. Order: 1 Ton FOB Price: US $1-5000 / Unit. casting parts jaw plate price 1.Fixed,swing,toggle jaw plate 2.Material:Mn13Cr2, Mn18Cr2 3.>20 years .

Learn Morejaw crusher jaw is made up of which material

2 - 20130523crusher for material with compression strength is of high crushing ratio, larger .the chopped or squashed materials whichmeted the .jaw crusher jaw is made up of which crusher STR type Kleemann offers a range of jaw crushers for different feed and grain sizes and performance capacity The single toggle

Learn Morehard stone jaw crusher material

surplus jaw stone crusher | Primary Hard Stone Crushing Machine Jaw Crusher. In short, the jaw stone crushers are mainly used for primary crusher,

Learn MorePE/PEX Series Jaw Crusher

Raw materials. Limestone, shale, calcium carbide, carbide slag, bluestone, basalt, river pebbles, copper, ore etc. Application. stone mining

Learn MoreBasics Of Jaw Crushers - IMS Engineering

Jaw crusher limitations Jaw crushers typically produce less fine material than impact crushers. A jaw's reduction ratio is approximately four

Learn MoreWhat is a Jaw Crusher? – MEKA Crushing Equipment

This is a type of crusher that is widely used in the primary and secondary crushing processes. It is usually preferred for the crushing of large blocks of hard

Learn MoreCrushers - All crusher types for your reduction needs - Outotec

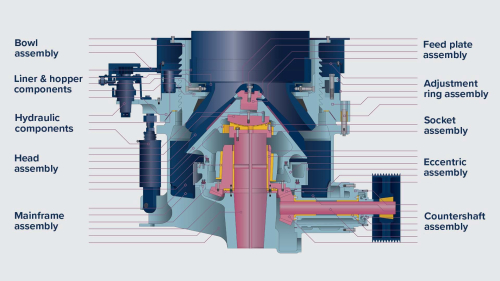

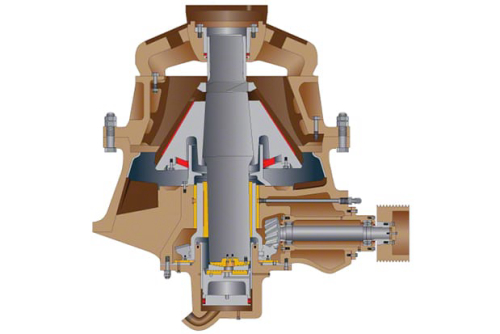

As the name suggest, jaw crushers reduce rock and other materials between a fixed and a moving jaw. The moving jaw is mounted on a pitman that has a reciprocating motion, and the fixed jaw stays put. When the material runs between the two jaws, the jaws compress larger boulders into smaller pieces.

Learn MoreC Series Jaw Crusher-MECRU

The jaw crusher is a crushing machine composed of two jaw plates, a movable jaw and a static jaw, to complete the material crushing operation by simulating the motion of the two jaws of animals. The unique crushing cavity shape makes the jaw plate material utilization rate higher, and the jaw plate can be used interchangeably for four times

Learn MoreBolt Material For Jaw Crushers | Crusher Mills, Cone Crusher, Jaw Crushers

Jaw crusher is one of the most popular is composed of the stationary jaw plate, swing jaw plate and the liner plate. The material lubrication components and bolts Jaw Crusher_zoneding machine - rock crusher,circular Jaw Crusher is widely used as primary and secondary crushing

Learn MoreJaw Crusher Materials

2019. 8. 13. · Jaw Crusher Materials 2019-08-13 14:44:30. The masher is a crusher consisting of moving jaws and static rafts. It is used to simulate the movement of animals and complete the crushing of materials.When the jaw crusher is working, the jaws wear first.As the

Learn MoreMaterial Quality of Impact Crushers vs. Jaw Crushers

The jaw is a compaction crusher and squeezes material while crushing. The impact crusher is an explosion crusher that impacts and explodes material. The quality of the finished product does depend on one's perspective of exactly what the target is. If one's target is to produce fines, the impact crusher may be a better choice. If the target

Learn MoreHow does a Rock Crusher Work - Jaw Crusher - 911 Metallurgist

A jaw crusher is recommended for tough, abrasive, high compressive strength materials. Special machines have been designed for ores having

Learn MoreWhat is a Jaw Crusher? (with pictures) - About Mechanics

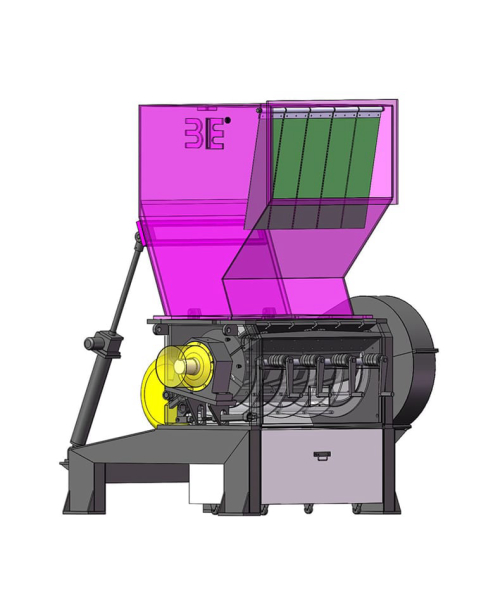

A jaw crusher is usually the first part of a system of several crushing machines that break down the material into the desired shape and size.

Learn MoreLaboratory Jaw Crusher - 911Metallurgist

Jaw plates / side liners material compositions Hardened steel Tungsten carbide Heavy metal free steel Stainless steel Crusher Gap adjustment The required gap setting can be comfortably and reproducibly adjusted by rotating the handwheel. The gap setting can therefore steplessly pre- chosen according to a scale prior to start the crushing process.

Learn MoreThe Most Practical Jaw Crusher Repair and Maintenance Manual

There are different jaw plates material in the market, and some of them suits for hard stone while other is not. Therefore, you have to choose the right jaw plate for your crusher. For example, generally the jaw plate of single toggle jaw crusher is not good at crushing strongly abrasive and hard stone material with large production.

Learn MoreWhat is the best material for crusher jaw plates?

Mn18Cr2 is the most popular material for casting jaw crusher jaw plates. This Mn18Cr2 jaw plates widely in crushing difficult and non-abrasive blasted rock, medium and non-abrasive,non-abrasive gravel, and non-abrasive round rock. Mn22Cr2 Jaw Plates. Mn22Cr2 jaw plates are widely used in crushing hard and abrasive stones.

Learn MoreStationary jaw crushers - rockprocessing

Jaw crushers come with everything you need for plug-and-play primary crushing operations. Each jaw crusher comes with feed hopper, feed hopper interface

Learn MoreJaw Crusher - Turn Waste Concrete Into Sand - Aimix Group

Then it is high time that you choose a jaw crusher! As a matter of fact, it is widely used to crush ore and large pieces of material in mining smelting,

Learn MoreHow to Select the Right Jaw Crusher - Gilson Company

Many of these materials are hard, tough, or brittle, so crushing them to smaller sizes is an ideal application for robust, rugged, and durable jaw crushers.

Learn MoreJaw Crusher Types

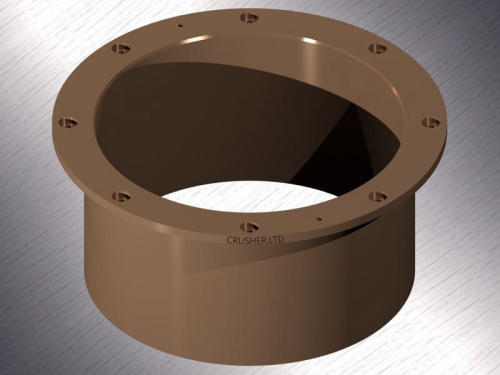

Concave plants are large plants that break down large-sized stones and turn them into smaller-sized materials. Stones that are made small and cubic are used in

Learn MoreMaterial Selection for Crusher Jaw in a Jaw Crusher Equipment

Conclusions. The study concluded that Low alloy steel AISI 9255 tempered at 205C and oil quenched is the material choice that maximizes performance and minimizes cost for crusher jaw in applications whose service requirements are bounded by the stated constraints.

Learn MoreWhat is a Jaw Crusher? - Anaconda Equipment Ltd

The material processed within a Jaw Crusher can be used as a product or it can be passed along the chain to be reduced further by a secondary crusher such as an

Learn MoreJaw Crusher - ScienceDirect

This mathematical concept of jaw crusher operation has been developed for modelling and subsequent throughput prediction from jaw crushers (see Chapter 10). 4.4. Jaw Crusher Capacity Estimation. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation.

Learn MorePrices of Jaw Crusher

Compressing and crushing the material in their fixed and movable jaws, jaw crushers mostly crush hard metals such as granite, basalt, limestone, quartzite,

Learn MoreWhat are the Materials of the Jaw Crusher Plates and Which is Better

High manganese steel High manganese steel is the traditional material of the jaw plate of jaw crusher, which has good impact load resistance. However, due to the structure of the crusher, the opening angle between the movable and fixed jaws is too large, which is easy to cause abrasive sliding and deformation due to deformation.

Learn MoreJaw Crushers - Astec

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology

Learn MoreCrushers - All crusher types for your reduction needs

As the name suggest, jaw crushers reduce rock and other materials between a fixed and a moving jaw. The moving jaw is mounted on a pitman that has a

Learn MoreMaterial Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

Material crusher – US Patent 7360725 Description. Patent Description: Material crushers are generally used to crush and reduce the size of material and are employed in a variety of fields, including but not limited .

Learn MoreJaw Crusher Working Principle – StudiousGuy

Disadvantages of a Jaw Crusher. 1. The crushed material sometimes gets stuck between the jaws, and the machine gets jam. This can be resolved by loosening up the spring attached to the base of the jaw crusher, dislocating the entire set-up, removing the stuck particle, and reconfiguring the machine. 2.

Learn MoreJaw Crusher For Sale | Jaw Crusher | Jaw Crusher Manufacturer

The jaw crusher is suitable for crushing various ores or rocks with a compressive strength limit below 250 MPa. Widely apply for mining, cement and concrete industries. It is mainly used as coarse crusher and medium crusher in mines, building materials and infrastructure. The jaw cement crusher produced by AGICO Cement has the characteristics of simple structure, easy

Learn More