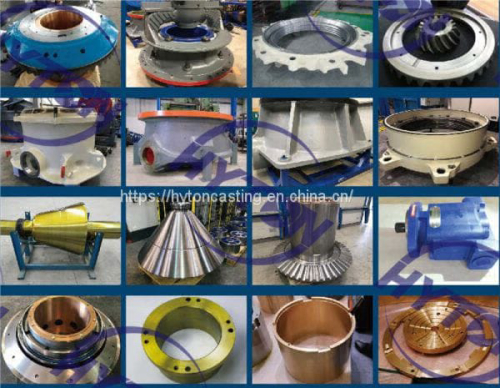

gyratory crusher maintenance

Gyratory crusher upgrades - Outotec

Go from MK I to MK nXt with our Superior primary gyratory crushers upgrades. Mix and match to suit your goals: better production, reliability & maintenance.

Learn MoreThe Most Practical Jaw Crusher Repair and

20/7/2022 · Inspection and maintenance of other parts Check whether the discharge port is blocked, remove the blockage in time, and keep the discharge unobstructed. Check whether

Learn MoreCrusher Service | Maintenance & Servicing | CMS Cepcor

CMS Cepcor® provides reliable crusher services, everything from routine maintenance to full crusher re-builds. For high-quality repairs contact us today. +44 (0) 1530 540116. 10:14 am GMT +44 (0) 1530 540116. Visit us at Bauma 2022, Munich, Germany 24th-30th October [X] Close Form Quick Contact To find out more about any of our services, contact us today by simply

Learn MorePDF Instruction Manual for Gyratory Crusher PXZ-1500IIPDF

carry out appropriate inspection, installation, operation and maintenance on the crusher and its ancillary equipment. The manual only contains basic operating techniques, which will help technical personnel to The gyratory crusher of CITIC Heavy Machinery company is mainly used in mines, quarries, metallurgy and other fields. During its

Learn More2. GYRATORY CRUSHERS - Metallurgist & Mineral Processing

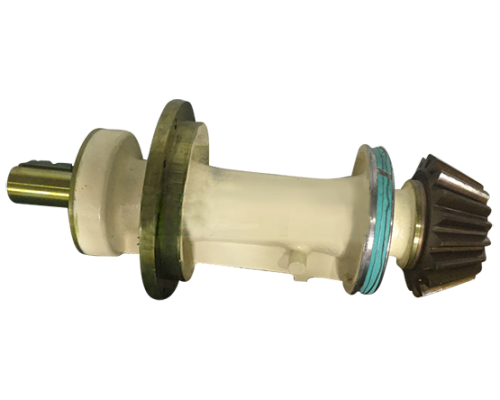

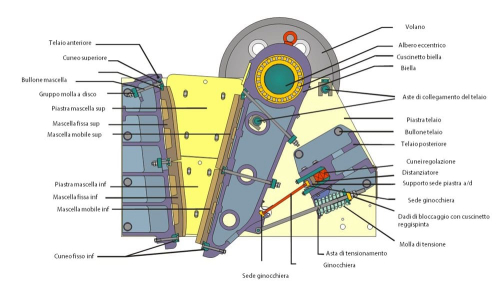

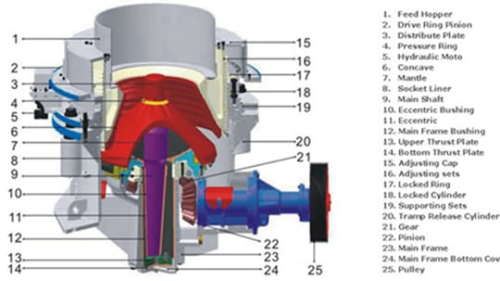

The parameters used in the basic design of a gyratory crusher are nip angle, feed rate, feed opening, closed-side setting, work index, and horsepower. The combination of the nip angle, feed opening, and closed-side setting determine the length of the crushing chamber and indirectly the length of the main shaft.

Learn MoreThe Most Practical Jaw Crusher Repair and Maintenance Manual

Inspection and maintenance of other parts Check whether the discharge port is blocked, remove the blockage in time, and keep the discharge unobstructed. Check whether the V-belt is loose. If it is too loose, you need tight it because loose belt will cause slippage. Whether the eccentric shaft is blocked.

Learn MoreConstruction Working and Maintenance of Crushers for

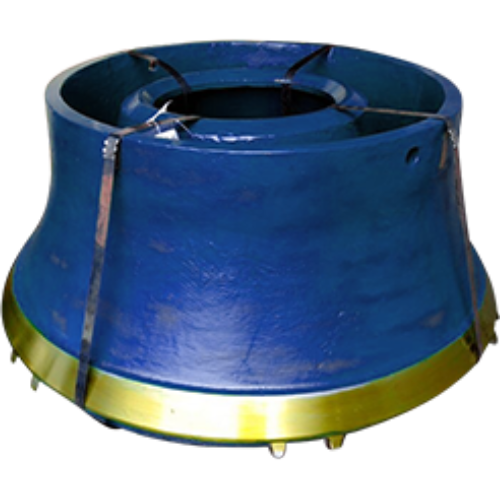

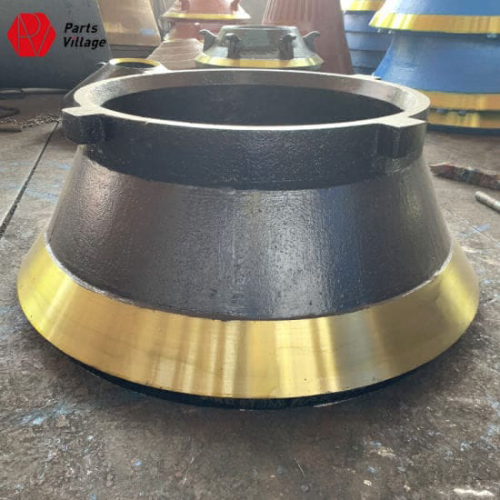

Gyratory crushers are designated by two numbers. These are the size of the feed opening (in inches) and the diameter of the mantle at its base (in inches). The feed material should be at

Learn MoreGyratory Crusher Maintenance

Primary gyratory crusher maintenance video. primary gyratory crusher maintenance south africa. Kolomela mine reduces liner replacement downtime and Mar 13, A major factor affecting crusher efficiency is the amount of downtime The longer it takes to replace the wear parts inside the chamber of a primary gyratory crusher during a maintenance

Learn MoreWhat is a Gyratory Crusher | Quarrying & Aggregates

It is difficult to repair and maintain, and the repair cost and the cost of wear parts are high. The high fuselage of the gyratory crusher results in high infrastructure costs such as foundations and workshops. Generally, aerial cranes are required to facilitate maintenance. Application of

Learn MoreHeavy duty, maintenance-friendly Gyratory Crusher

High-power crushing and easy maintenance with the Gyratory Crusher NT Get the best features of the previous model with added safety and usability functions.

Learn MorePDF Construction Working and Maintenance of Crushers for Crushing Bulk ...PDF

Gyratory crushers are designated by two numbers. These are the size of the feed opening (in inches) and the diameter of the mantle at its base (in inches). The feed material should be at least 15 to 20% smaller than the width of the feed opening. Gyratory crusher's discharge setting is referred to as the Open Side Setting (OSS).

Learn MoreGyratory Crusher Services I Service - thyssenkrupp Mining

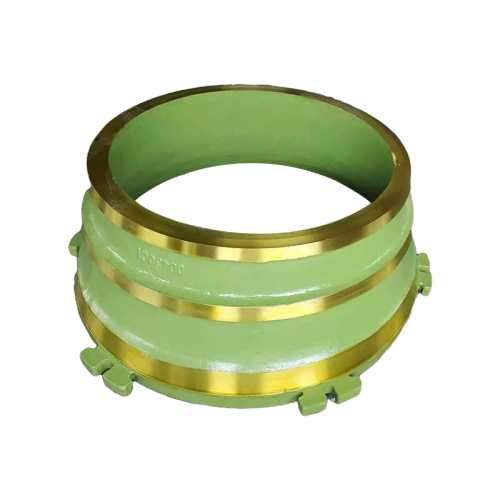

Stop your crusher, start the disassembling Replace the installed shells by preassembled spare shells Assemble the crusher – go back in operation Your added value Increased availability

Learn MoreGyratory Crusher Maintenance

Gyratory Crusher Main Shaft. the gyratory crusher ts is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions. it is designed so that you can easily access and remove the eccentric assembly, bushings and hydraulic piston through the top of the crusher, hence the name

Learn MoreGYRATORY CONE CRUSHER SHUTDOWN MAINTENANCE

viral #viralvideos # ironore #kobelcogyratoryconecrusher #kobelcocrusher #ironoremining #ironorecrushing #ironoreprocessing #maintenance #shutdownma

Learn MoreGyratory Crushers TC, NT and TS model crushers

the basic concept behind adjust to temperature fluctua- crushing operations because of the gyratory crusher remains tions and wear, requiring minimal large capacity reservoirs and high the same as it did during its in- maintenance. oil flow rates to eccentric and ception, but the machine is • mainshaftassembly: the shaft bushings. entirely

Learn MoreThe basics of crusher maintenance ~ primary and secondary

Schmidt's top 10 cone crusher maintenance tips. • It is no surprise the first tip is doing comprehensive daily inspections.

Learn MoreGyratory Crushers - Dorr-Oliver Eimco - PDF Catalogs

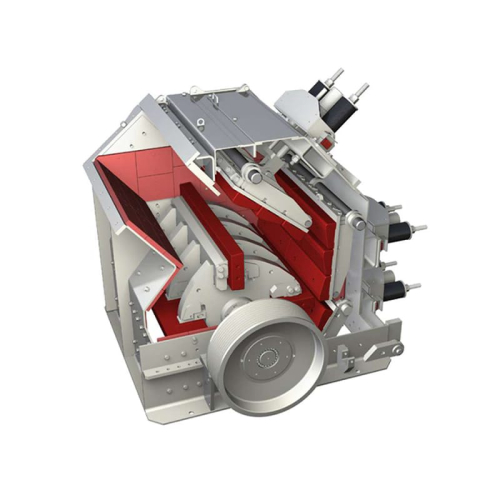

The "Top-Service" (TS) Line is the newest generation of Fuller-Traylor Gyratory Crushers from FLSmidth. This entire Gyratory Crusher is engineered from the

Learn MoreRegular crusher maintenance integral to reliability

Jones advises: “Always ensure the wear parts are fastened into the machine properly. With jaw crushers, if you allow the jaw dies to move during

Learn MoreTLC for Primary Crushers | E & MJ

A gyratory crusher is a significant investment for any mine. Poor maintenance can result in unplanned shutdowns for repairs, premature failures and

Learn MoreGYRATORY CRUSHER - FULLER MINING

High-power crushing and easy maintenance with the Gyratory Crusher. Get the best features of the previous model with added safety and usability functions.

Learn MoreGyratory Crusher - an overview | ScienceDirect Topics

A gyratory crusher includes a solid cone set on a revolving shaft and Maintenance of the wear components in both gyratory and cone crushers is one of

Learn MoreHOPPER CLEANING OF GYRATORY CONE CRUSHER 4 SCHEDULED

9/1/2022 · HOPPER CLEANING OF GYRATORY CONE CRUSHER FOR SCHEDULED MAINTENANCE OF RING SEALINGPlease subscribe#technical_info_fe2o3#crusher#crushing#miningengine

Learn Moreprimary gyratory crusher maintenance south africa

Primary Crushing Mineral Processing & Metallurgy. The term "primary crusher," by definition,might embrace any type and size of crushing machine.The term implies that at least two

Learn MoreCommon faults and maintenance items of gyratory crusher

29/8/2022 · The minor repair period of the gyratory crusher is generally 15 to 20 days, which is mainly determined by the wear of some wear-resistant parts in the equipment. The work content of the minor repair is mainly to wear, maintain and lubricate the dustproof device, suspension device, nylon rod and related supporting parts of the crusher.

Learn MoreGyratory Crusher

PERFORMANCE why choose our Gyratory crusher: Efficient and Intelligent Production. High Output Yet, Low Crushing Costs. Simpler Operation and Maintenance. Sufficient Supply of Spare Parts, Worry-Free Operation. Strong Adaptability, Applicable for Severe Crushing Conditions. Able to Work Continuously under High Intensity, It has longer service life.

Learn MoreGyratory Crusher

why choose our Gyratory crusher: Efficient and Intelligent Production. High Output Yet, Low Crushing Costs. Simpler Operation and Maintenance. Sufficient Supply of Spare Parts, Worry-Free Operation. Strong Adaptability, Applicable for Severe Crushing Conditions. Able to Work Continuously under High Intensity, It has longer service life.

Learn MoreGyratory Crusher Services I Service

Take advantage with these gyratory crusher services · Rock-Box Spider Cap & Arm Liner · Crushing Chamber Optimization · Wear Parts Optimization

Learn MoreCone Crusher Maintenance Guide

gyratory crusher maintenance manual | Mobile Crusher Philippines. Gyratory Crusher is used in quarry as quarry crushing equipment. Gyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center

Learn MoreGyratory Crusher Pro | manufactor | thyssenkrupp Mining Technologies

The design of the gyratory crushers and jaw gyratory crushers is based on more than one hundred years of experience. thyssenkrupp gyratory crushers represent today's state-of-the-art. They are designed for high throughput rates and high crushing ratios at low operating and maintenance costs. Maintenance friendly design

Learn MoreTips for Crusher Maintenance - Thomasnet

28/11/ · Gyratory Crushers Check spider bushing clearance monthly, every 500 hours, or with every mantle change. Whichever comes first. Monitor and maintain bushing lubrication levels every day (about 1.4" above bushing flange). Make sure "extreme pressure" additive is added. Check balance cylinder (s) every 30 days of operation.

Learn More